![[YOUR IMAGE HERE]](assets/images/item_11783.jpg)

![[YOUR IMAGE HERE]](assets/images/item_11328.png)

![[YOUR IMAGE HERE]](assets/images/item_11871.jpg)

![[YOUR IMAGE HERE]](assets/images/item_11338.png)

![[YOUR IMAGE HERE]](assets/images/item_11929.jpg)

![[YOUR IMAGE HERE]](assets/images/item_11494.png)

![[YOUR IMAGE HERE]](assets/images/item_11900.png)

![[YOUR IMAGE HERE]](assets/images/item_11346.png)

![[YOUR IMAGE HERE]](assets/images/item_11753.jpg)

![[YOUR IMAGE HERE]](assets/images/item_11319.png)

![[YOUR IMAGE HERE]](assets/images/item_11957.jpg)

![[YOUR IMAGE HERE]](assets/images/item_11274.png)

Navy’s T-54A Ushers in New Era of Pilot Training

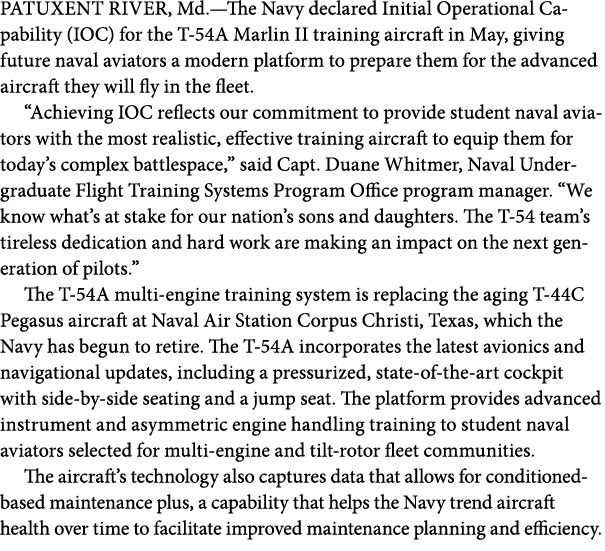

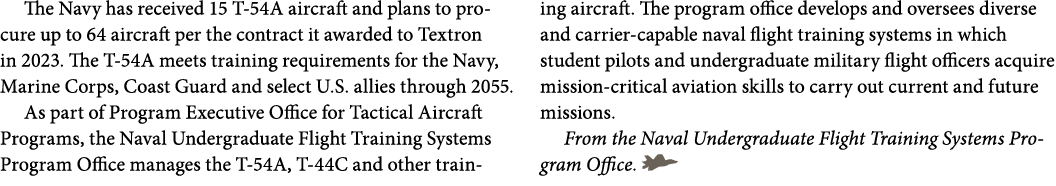

PATUXENT RIVER, Md.—The Navy declared Initial Operational Capability (IOC) for the T-54A Marlin II training aircraft in May, giving future naval aviators a modern platform to prepare them for the advanced aircraft they will fly in the fleet.

“Achieving IOC reflects our commitment to provide student naval aviators with the most realistic, effective training aircraft to equip them for today’s complex battlespace,” said Capt. Duane Whitmer, Naval Undergraduate Flight Training Systems Program Office program manager. “We know what’s at stake for our nation’s sons and daughters. The T-54 team’s tireless dedication and hard work are making an impact on the next generation of pilots.”

The T-54A multi-engine training system is replacing the aging T-44C Pegasus aircraft at Naval Air Station Corpus Christi, Texas, which the Navy has begun to retire. The T-54A incorporates the latest avionics and navigational updates, including a pressurized, state-of-the-art cockpit with side-by-side seating and a jump seat. The platform provides advanced instrument and asymmetric engine handling training to student naval aviators selected for multi-engine and tilt-rotor fleet communities.

The aircraft’s technology also captures data that allows for conditioned-based maintenance plus, a capability that helps the Navy trend aircraft health over time to facilitate improved maintenance planning and efficiency.

The Navy has received 15 T-54A aircraft and plans to procure up to 64 aircraft per the contract it awarded to Textron in 2023. The T-54A meets training requirements for the Navy, Marine Corps, Coast Guard and select U.S. allies through 2055.

As part of Program Executive Office for Tactical Aircraft Programs, the Naval Undergraduate Flight Training Systems Program Office manages the T-54A, T-44C and other training aircraft. The program office develops and oversees diverse and carrier-capable naval flight training systems in which student pilots and undergraduate military flight officers acquire mission-critical aviation skills to carry out current and future missions.

From the Naval Undergraduate Flight Training Systems Program Office.

SCHRIEVER SPACE FORCE BASE, Colo.—Navy Lt. Cmdr. Matthew Dring, National Space Defense Center operations integrations chief, was selected to attend the weapons instructor course at the U.S. Air Force Weapons School’s 328th Weapons Squadron.

The 328th Weapons Squadron, based at Nellis Air Force Base, Nevada, is part of Space Training and Readiness Command’s Space Delta 1. As the weapons school for the U.S. Space Force, it offers the Space Superiority Weapons Instructor Course and the Space Warfighter Advanced Instructor Course. Students undergo five to six months of rigorous training before becoming weapons officers—experts in tactical and operational space integration.

Dring’s selection for the course marks a significant step forward in joint force education and operational space integration. As one of the first Navy officers to attend, he’s forging a new path for interoperability between services, bridging the gap between space asset owners and users.

“When you look at the space domain, the 328th Weapons Squadron represents the pinnacle of space excellence,” Dring said. “For me, it was natural to want to go to the best school.”

Dring highlighted the importance of joint training and said attending a sister service program will allow him and his fellow Navy selectee to approach challenges from unique operational perspectives.

He credits his Navy training, especially in flight school and information warfare, as strong preparation for the rigorous program. Despite pre-course jitters, he remains focused on adapting his naval expertise to meet Space Force expectations.

“My hope is that we are not the only, but the first, to go through this program. It’s an incredible opportunity to train side by side with other services,” Dring said. “Not only will we be able to learn the same way, but ultimately, we’ll be able to integrate better on the battlefield.”

His participation signals a growing emphasis on interservice cooperation as space operations become increasingly integral to national security. Dring hopes his selection will pave the way for future Navy officers to attend the course, strengthening collaboration and battlefield integration across domains.

Written by Bridget Bonnette with the National Space Defense Center.

Director, Air Warfare

Editor in Chief

Editorial Board

Naval Aviation News Staff

Contributing Editor

Columnist

Cmdr. Peter B. Mersky, USNR (Ret.), Book Review Editor

Submission Guidelines

Commands may send news and announcements such as awards, rescues, milestones and other achievements to navy_nannews@navy.mil. Approved photos of Naval Aviation-oriented activities are always welcome. For longer feature articles, contact the editor in advance. Military contributors should forward articles about their commands only after internal security review and with command approval. For more information, contact us at navy_nannews@navy.mil.

Naval Aviation News (USPS 323-310; ISSN 0028-1417) is published quarterly for the Chief of Naval Operations by the Naval Air Systems Command. The Secretary of the Navy has determined that this publication is necessary in the transaction of business required by law. The use of a name of any specific manufacturer, commercial product, commodity or service in this publication does not imply endorsement by the Navy. Any opinions herein are those of the authors, and do not necessarily represent the views of Naval Aviation News, the Department of the Navy or the Department of Defense.

Please visit our website at:

https://navalaviationnews.navy.mil to view our current issue and download archived copies of the publication.

Approved for public release: SPR No. 2025-0553

NAVAIR Public Release Distribution Statement A—

“Approved for public release; distribution is unlimited”

Send your feedback to: navy_nannews@us.navy.mil

Navy’s T-54A Ushers in New Era of Pilot Training

PATUXENT RIVER, Md.—The Navy declared Initial Operational Capability (IOC) for the T-54A Marlin II training aircraft in May, giving future naval aviators a modern platform to prepare them for the advanced aircraft they will fly in the fleet.

“Achieving IOC reflects our commitment to provide student naval aviators with the most realistic, effective training aircraft to equip them for today’s complex battlespace,” said Capt. Duane Whitmer, Naval Undergraduate Flight Training Systems Program Office program manager. “We know what’s at stake for our nation’s sons and daughters. The T-54 team’s tireless dedication and hard work are making an impact on the next generation of pilots.”

The T-54A multi-engine training system is replacing the aging T-44C Pegasus aircraft at Naval Air Station Corpus Christi, Texas, which the Navy has begun to retire. The T-54A incorporates the latest avionics and navigational updates, including a pressurized, state-of-the-art cockpit with side-by-side seating and a jump seat. The platform provides advanced instrument and asymmetric engine handling training to student naval aviators selected for multi-engine and tilt-rotor fleet communities.

The aircraft’s technology also captures data that allows for conditioned-based maintenance plus, a capability that helps the Navy trend aircraft health over time to facilitate improved maintenance planning and efficiency.

The Navy has received 15 T-54A aircraft and plans to procure up to 64 aircraft per the contract it awarded to Textron in 2023. The T-54A meets training requirements for the Navy, Marine Corps, Coast Guard and select U.S. allies through 2055.

As part of Program Executive Office for Tactical Aircraft Programs, the Naval Undergraduate Flight Training Systems Program Office manages the T-54A, T-44C and other training aircraft. The program office develops and oversees diverse and carrier-capable naval flight training systems in which student pilots and undergraduate military flight officers acquire mission-critical aviation skills to carry out current and future missions.

From the Naval Undergraduate Flight Training Systems Program Office.

SCHRIEVER SPACE FORCE BASE, Colo.—Navy Lt. Cmdr. Matthew Dring, National Space Defense Center operations integrations chief, was selected to attend the weapons instructor course at the U.S. Air Force Weapons School’s 328th Weapons Squadron.

The 328th Weapons Squadron, based at Nellis Air Force Base, Nevada, is part of Space Training and Readiness Command’s Space Delta 1. As the weapons school for the U.S. Space Force, it offers the Space Superiority Weapons Instructor Course and the Space Warfighter Advanced Instructor Course. Students undergo five to six months of rigorous training before becoming weapons officers—experts in tactical and operational space integration.

Dring’s selection for the course marks a significant step forward in joint force education and operational space integration. As one of the first Navy officers to attend, he’s forging a new path for interoperability between services, bridging the gap between space asset owners and users.

“When you look at the space domain, the 328th Weapons Squadron represents the pinnacle of space excellence,” Dring said. “For me, it was natural to want to go to the best school.”

Dring highlighted the importance of joint training and said attending a sister service program will allow him and his fellow Navy selectee to approach challenges from unique operational perspectives.

He credits his Navy training, especially in flight school and information warfare, as strong preparation for the rigorous program. Despite pre-course jitters, he remains focused on adapting his naval expertise to meet Space Force expectations.

“My hope is that we are not the only, but the first, to go through this program. It’s an incredible opportunity to train side by side with other services,” Dring said. “Not only will we be able to learn the same way, but ultimately, we’ll be able to integrate better on the battlefield.”

His participation signals a growing emphasis on interservice cooperation as space operations become increasingly integral to national security. Dring hopes his selection will pave the way for future Navy officers to attend the course, strengthening collaboration and battlefield integration across domains.

Written by Bridget Bonnette with the National Space Defense Center.

Director, Air Warfare

Editor in Chief

Editorial Board

Naval Aviation News Staff

Contributing Editor

Columnist

Cmdr. Peter B. Mersky, USNR (Ret.), Book Review Editor

Submission Guidelines

Commands may send news and announcements such as awards, rescues, milestones and other achievements to navy_nannews@navy.mil. Approved photos of Naval Aviation-oriented activities are always welcome. For longer feature articles, contact the editor in advance. Military contributors should forward articles about their commands only after internal security review and with command approval. For more information, contact us at navy_nannews@navy.mil.

Naval Aviation News (USPS 323-310; ISSN 0028-1417) is published quarterly for the Chief of Naval Operations by the Naval Air Systems Command. The Secretary of the Navy has determined that this publication is necessary in the transaction of business required by law. The use of a name of any specific manufacturer, commercial product, commodity or service in this publication does not imply endorsement by the Navy. Any opinions herein are those of the authors, and do not necessarily represent the views of Naval Aviation News, the Department of the Navy or the Department of Defense.

Please visit our website at:

https://navalaviationnews.navy.mil to view our current issue and download archived copies of the publication.

Approved for public release: SPR No. 2025-0553

NAVAIR Public Release Distribution Statement A—

“Approved for public release; distribution is unlimited”

Send your feedback to: navy_nannews@us.navy.mil

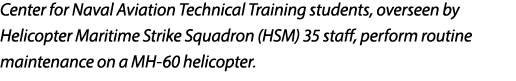

CNATTU North Island, HSM-35 Partner to Build Safer, More Prepared Fleet

SAN DIEGO—A unique collaboration between the Center for Naval Aviation Technical Training Unit (CNATTU) North Island and Helicopter Maritime Strike Squadron (HSM) 35 is proving to be a win-win initiative that strengthens fleet readiness, enhances safety and prepares the next generation of aircraft maintainers through hands-on experience.

The partnership began in December 2023, when HSM-35 Executive Officer Cmdr. Donald Safford met CNATTU North Island Commanding Officer Cmdr. Robert Kersey during the Prospective Commanding Officer training pipeline. Their discussion about common manning and training challenges laid the groundwork for establishing a program that would send CNATTU students on hold to HSM-35 for real-world fleet exposure.

“HSM-35 had an unscheduled deployment and was short on personnel,” Safford said. “Bringing in CNATTU students not only helped ease the workload but [also] gave our team leadership and instructor opportunities—training students in areas like flight line safety, corrosion control and ‘by the book’ maintenance.”

For the students, the experience has been equally valuable. Several sailors shared they gained a better understanding of their rating, saw broader applications of what they learned, and felt more prepared mentally for their first fleet assignments.

Aviation Machinist’s Mate Elijah Taa said, “I really did enjoy going to HSM-35. I made some friends and gained a lot of knowledge.”

Aviation Structural Mechanic Air Recruit Matthew Ward said the experience gave him a better picture of what to expect in the fleet, while Aviation Electrician’s Mate Airman Apprentice Nathan O’Meara emphasized despite being new and underprepared, he immediately felt like a valued member of the team.

Safford underscored the collaboration directly supports the Commander, Naval Air Forces, or “Air Boss’s,” initiative to reduce Class C aviation ground mishaps (AGMs) by 50 percent.

“Safety and maintenance are not theoretical here—they must be practiced and demonstrated,” Safford said. “Our sailors teach CNATTU students procedural compliance and reinforce safe, by-the-book maintenance, which benefits everyone.”

Feedback from the HSM-35 team has also been overwhelmingly positive.

“One of our E-5s told me, ‘They’re [students] so nice to have. It’s going to be sad to see them go,’” Safford said. “And when I see a new face in a cranial, I assume it’s a new check-in—that’s how integrated they’ve become.”

Areas for improvement include expanding opportunities for more hands-on involvement and having CNATTU instructors teach at the squadron during major maintenance periods. But the foundation that has been built is strong.

“Now, when we know we’ll be pulling a gearbox or replacing a rotor head, we notify CNATTU so students can observe,” Safford said. “It’s more efficient and relevant.”

This partnership exemplifies the Navy’s commitment to warfighting readiness, safety and sailor development.

“We’re investing in our people,” Safford said. “This is how we build a more adaptable, mission-ready force.”

Written by Chief Petty Officer Edna Rodriguez with the Center for Naval Aviation Technical Training, North Island, California.

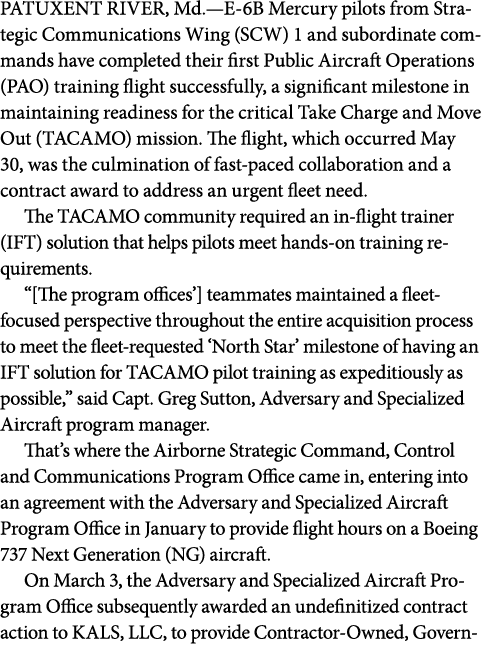

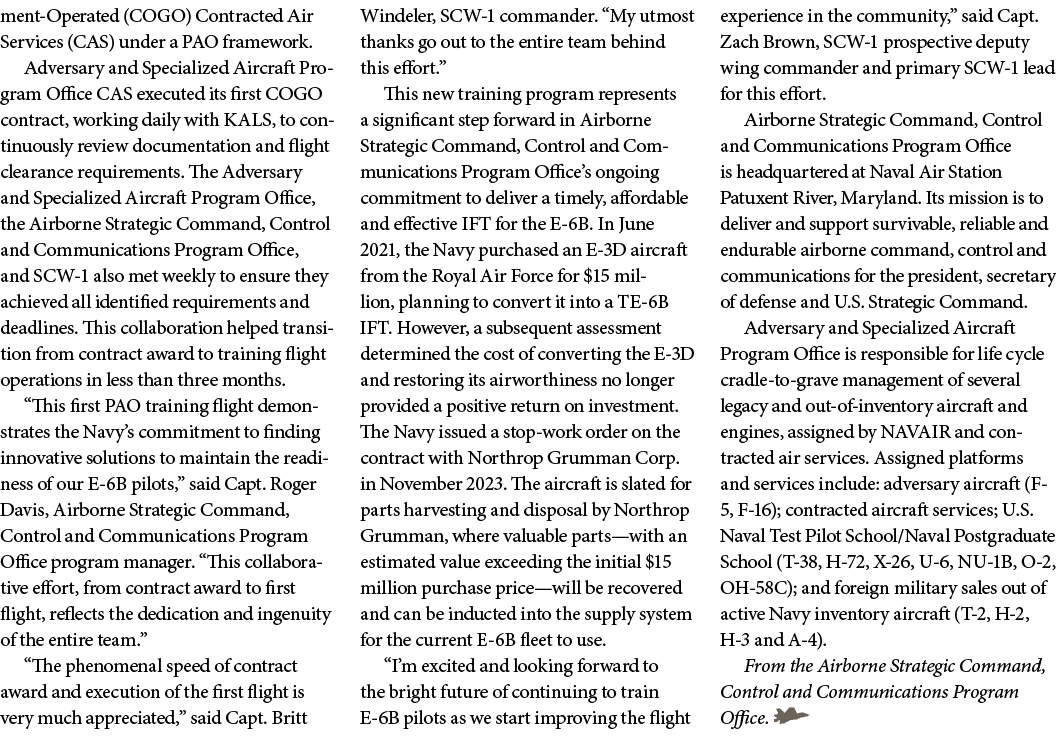

Collaboration, New Training Asset Boost E-6B Pilot Readiness

PATUXENT RIVER, Md.—E-6B Mercury pilots from Strategic Communications Wing (SCW) 1 and subordinate commands have completed their first Public Aircraft Operations (PAO) training flight successfully, a significant milestone in maintaining readiness for the critical Take Charge and Move Out (TACAMO) mission. The flight, which occurred May 30, was the culmination of fast-paced collaboration and a contract award to address an urgent fleet need.

The TACAMO community required an in-flight trainer (IFT) solution that helps pilots meet hands-on training requirements.

“[The program offices’] teammates maintained a fleet-focused perspective throughout the entire acquisition process to meet the fleet-requested ‘North Star’ milestone of having an IFT solution for TACAMO pilot training as expeditiously as possible,” said Capt. Greg Sutton, Adversary and Specialized Aircraft program manager.

That’s where the Airborne Strategic Command, Control and Communications Program Office came in, entering into an agreement with the Adversary and Specialized Aircraft Program Office in January to provide flight hours on a Boeing 737 Next Generation (NG) aircraft.

On March 3, the Adversary and Specialized Aircraft Program Office subsequently awarded an undefinitized contract action to KALS, LLC, to provide Contractor-Owned, Government-Operated (COGO) Contracted Air Services (CAS) under a PAO framework.

Adversary and Specialized Aircraft Program Office CAS executed its first COGO contract, working daily with KALS, to continuously review documentation and flight clearance requirements. The Adversary and Specialized Aircraft Program Office, the Airborne Strategic Command, Control and Communications Program Office, and SCW-1 also met weekly to ensure they achieved all identified requirements and deadlines. This collaboration helped transition from contract award to training flight operations in less than three months.

“This first PAO training flight demonstrates the Navy’s commitment to finding innovative solutions to maintain the readiness of our E-6B pilots,” said Capt. Roger Davis, Airborne Strategic Command, Control and Communications Program Office program manager. “This collaborative effort, from contract award to first flight, reflects the dedication and ingenuity of the entire team.”

“The phenomenal speed of contract award and execution of the first flight is very much appreciated,” said Capt. Britt Windeler, SCW-1 commander. “My utmost thanks go out to the entire team behind this effort.”

This new training program represents a significant step forward in Airborne Strategic Command, Control and Communications Program Office’s ongoing commitment to deliver a timely, affordable and effective IFT for the E-6B. In June 2021, the Navy purchased an E-3D aircraft from the Royal Air Force for $15 million, planning to convert it into a TE-6B IFT. However, a subsequent assessment determined the cost of converting the E-3D and restoring its airworthiness no longer provided a positive return on investment. The Navy issued a stop-work order on the contract with Northrop Grumman Corp. in November 2023. The aircraft is slated for parts harvesting and disposal by Northrop Grumman, where valuable parts—with an estimated value exceeding the initial $15 million purchase price—will be recovered and can be inducted into the supply system for the current E-6B fleet to use.

“I’m excited and looking forward to the bright future of continuing to train E-6B pilots as we start improving the flight experience in the community,” said Capt. Zach Brown, SCW-1 prospective deputy wing commander and primary SCW-1 lead for this effort.

Airborne Strategic Command, Control and Communications Program Office is headquartered at Naval Air Station Patuxent River, Maryland. Its mission is to deliver and support survivable, reliable and endurable airborne command, control and communications for the president, secretary of defense and U.S. Strategic Command.

Adversary and Specialized Aircraft Program Office is responsible for life cycle cradle-to-grave management of several legacy and out-of-inventory aircraft and engines, assigned by NAVAIR and contracted air services. Assigned platforms and services include: adversary aircraft (F-5, F-16); contracted aircraft services; U.S. Naval Test Pilot School/Naval Postgraduate School (T-38, H-72, X-26, U-6, NU-1B, O-2, OH-58C); and foreign military sales out of active Navy inventory aircraft (T-2, H-2, H-3 and A-4).

From the Airborne Strategic Command, Control and Communications Program Office.

![Feedback from the HSM 35 team has also been overwhelmingly positive. “One of our E 5s told me, ‘They’re [students] so...](assets/images/item_13395.png)

CNATTU North Island, HSM-35 Partner to Build Safer, More Prepared Fleet

SAN DIEGO—A unique collaboration between the Center for Naval Aviation Technical Training Unit (CNATTU) North Island and Helicopter Maritime Strike Squadron (HSM) 35 is proving to be a win-win initiative that strengthens fleet readiness, enhances safety and prepares the next generation of aircraft maintainers through hands-on experience.

The partnership began in December 2023, when HSM-35 Executive Officer Cmdr. Donald Safford met CNATTU North Island Commanding Officer Cmdr. Robert Kersey during the Prospective Commanding Officer training pipeline. Their discussion about common manning and training challenges laid the groundwork for establishing a program that would send CNATTU students on hold to HSM-35 for real-world fleet exposure.

“HSM-35 had an unscheduled deployment and was short on personnel,” Safford said. “Bringing in CNATTU students not only helped ease the workload but [also] gave our team leadership and instructor opportunities—training students in areas like flight line safety, corrosion control and ‘by the book’ maintenance.”

For the students, the experience has been equally valuable. Several sailors shared they gained a better understanding of their rating, saw broader applications of what they learned, and felt more prepared mentally for their first fleet assignments.

Aviation Machinist’s Mate Elijah Taa said, “I really did enjoy going to HSM-35. I made some friends and gained a lot of knowledge.”

Aviation Structural Mechanic Air Recruit Matthew Ward said the experience gave him a better picture of what to expect in the fleet, while Aviation Electrician’s Mate Airman Apprentice Nathan O’Meara emphasized despite being new and underprepared, he immediately felt like a valued member of the team.

Safford underscored the collaboration directly supports the Commander, Naval Air Forces, or “Air Boss’s,” initiative to reduce Class C aviation ground mishaps (AGMs) by 50 percent.

“Safety and maintenance are not theoretical here—they must be practiced and demonstrated,” Safford said. “Our sailors teach CNATTU students procedural compliance and reinforce safe, by-the-book maintenance, which benefits everyone.”

Feedback from the HSM-35 team has also been overwhelmingly positive.

“One of our E-5s told me, ‘They’re [students] so nice to have. It’s going to be sad to see them go,’” Safford said. “And when I see a new face in a cranial, I assume it’s a new check-in—that’s how integrated they’ve become.”

Areas for improvement include expanding opportunities for more hands-on involvement and having CNATTU instructors teach at the squadron during major maintenance periods. But the foundation that has been built is strong.

“Now, when we know we’ll be pulling a gearbox or replacing a rotor head, we notify CNATTU so students can observe,” Safford said. “It’s more efficient and relevant.”

This partnership exemplifies the Navy’s commitment to warfighting readiness, safety and sailor development.

“We’re investing in our people,” Safford said. “This is how we build a more adaptable, mission-ready force.”

Written by Chief Petty Officer Edna Rodriguez with the Center for Naval Aviation Technical Training, North Island, California.

Collaboration, New Training Asset Boost E-6B Pilot Readiness

PATUXENT RIVER, Md.—E-6B Mercury pilots from Strategic Communications Wing (SCW) 1 and subordinate commands have completed their first Public Aircraft Operations (PAO) training flight successfully, a significant milestone in maintaining readiness for the critical Take Charge and Move Out (TACAMO) mission. The flight, which occurred May 30, was the culmination of fast-paced collaboration and a contract award to address an urgent fleet need.

The TACAMO community required an in-flight trainer (IFT) solution that helps pilots meet hands-on training requirements.

“[The program offices’] teammates maintained a fleet-focused perspective throughout the entire acquisition process to meet the fleet-requested ‘North Star’ milestone of having an IFT solution for TACAMO pilot training as expeditiously as possible,” said Capt. Greg Sutton, Adversary and Specialized Aircraft program manager.

That’s where the Airborne Strategic Command, Control and Communications Program Office came in, entering into an agreement with the Adversary and Specialized Aircraft Program Office in January to provide flight hours on a Boeing 737 Next Generation (NG) aircraft.

On March 3, the Adversary and Specialized Aircraft Program Office subsequently awarded an undefinitized contract action to KALS, LLC, to provide Contractor-Owned, Government-Operated (COGO) Contracted Air Services (CAS) under a PAO framework.

Adversary and Specialized Aircraft Program Office CAS executed its first COGO contract, working daily with KALS, to continuously review documentation and flight clearance requirements. The Adversary and Specialized Aircraft Program Office, the Airborne Strategic Command, Control and Communications Program Office, and SCW-1 also met weekly to ensure they achieved all identified requirements and deadlines. This collaboration helped transition from contract award to training flight operations in less than three months.

“This first PAO training flight demonstrates the Navy’s commitment to finding innovative solutions to maintain the readiness of our E-6B pilots,” said Capt. Roger Davis, Airborne Strategic Command, Control and Communications Program Office program manager. “This collaborative effort, from contract award to first flight, reflects the dedication and ingenuity of the entire team.”

“The phenomenal speed of contract award and execution of the first flight is very much appreciated,” said Capt. Britt Windeler, SCW-1 commander. “My utmost thanks go out to the entire team behind this effort.”

This new training program represents a significant step forward in Airborne Strategic Command, Control and Communications Program Office’s ongoing commitment to deliver a timely, affordable and effective IFT for the E-6B. In June 2021, the Navy purchased an E-3D aircraft from the Royal Air Force for $15 million, planning to convert it into a TE-6B IFT. However, a subsequent assessment determined the cost of converting the E-3D and restoring its airworthiness no longer provided a positive return on investment. The Navy issued a stop-work order on the contract with Northrop Grumman Corp. in November 2023. The aircraft is slated for parts harvesting and disposal by Northrop Grumman, where valuable parts—with an estimated value exceeding the initial $15 million purchase price—will be recovered and can be inducted into the supply system for the current E-6B fleet to use.

“I’m excited and looking forward to the bright future of continuing to train E-6B pilots as we start improving the flight experience in the community,” said Capt. Zach Brown, SCW-1 prospective deputy wing commander and primary SCW-1 lead for this effort.

Airborne Strategic Command, Control and Communications Program Office is headquartered at Naval Air Station Patuxent River, Maryland. Its mission is to deliver and support survivable, reliable and endurable airborne command, control and communications for the president, secretary of defense and U.S. Strategic Command.

Adversary and Specialized Aircraft Program Office is responsible for life cycle cradle-to-grave management of several legacy and out-of-inventory aircraft and engines, assigned by NAVAIR and contracted air services. Assigned platforms and services include: adversary aircraft (F-5, F-16); contracted aircraft services; U.S. Naval Test Pilot School/Naval Postgraduate School (T-38, H-72, X-26, U-6, NU-1B, O-2, OH-58C); and foreign military sales out of active Navy inventory aircraft (T-2, H-2, H-3 and A-4).

From the Airborne Strategic Command, Control and Communications Program Office.

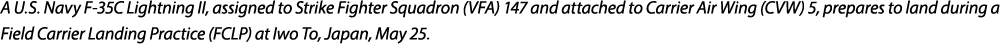

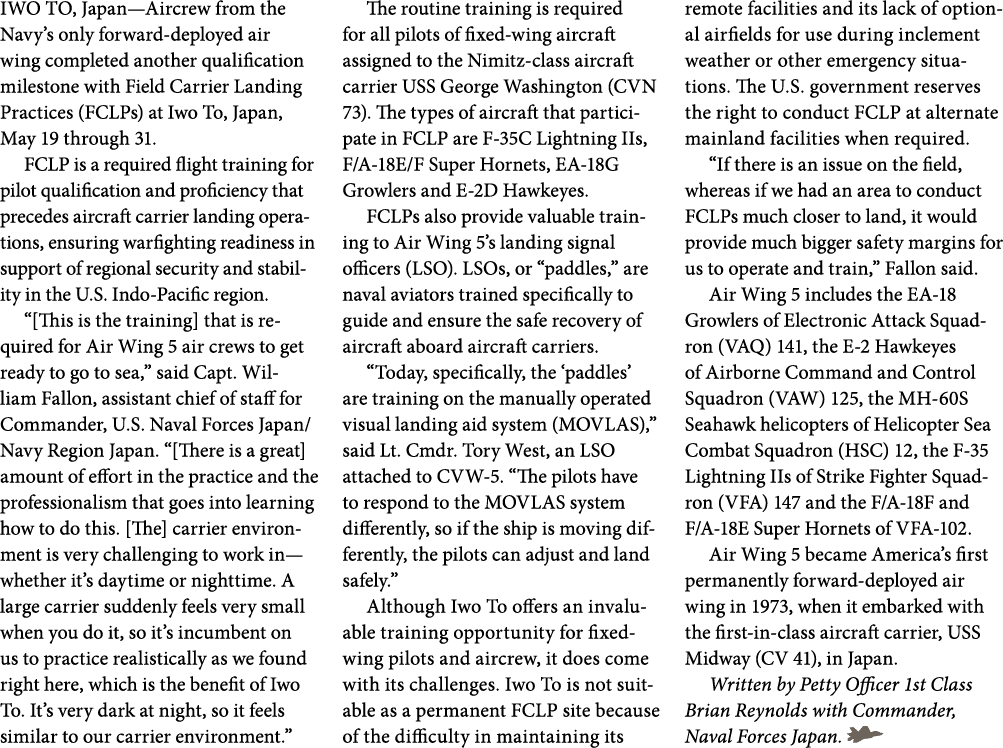

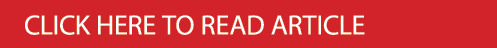

Carrier Air Wing 5 Operates at Iwo To

IWO TO, Japan—Aircrew from the Navy’s only forward-deployed air wing completed another qualification milestone with Field Carrier Landing Practices (FCLPs) at Iwo To, Japan, May 19 through 31.

FCLP is a required flight training for pilot qualification and proficiency that precedes aircraft carrier landing operations, ensuring warfighting readiness in support of regional security and stability in the U.S. Indo-Pacific region.

“[This is the training] that is required for Air Wing 5 air crews to get ready to go to sea,” said Capt. William Fallon, assistant chief of staff for Commander, U.S. Naval Forces Japan/Navy Region Japan. “[There is a great] amount of effort in the practice and the professionalism that goes into learning how to do this. [The] carrier environment is very challenging to work in—whether it’s daytime or nighttime. A large carrier suddenly feels very small when you do it, so it’s incumbent on us to practice realistically as we found right here, which is the benefit of Iwo To. It’s very dark at night, so it feels similar to our carrier environment.”

The routine training is required for all pilots of fixed-wing aircraft assigned to the Nimitz-class aircraft carrier USS George Washington (CVN 73). The types of aircraft that participate in FCLP are F-35C Lightning IIs, F/A-18E/F Super Hornets, EA-18G Growlers and E-2D Hawkeyes.

FCLPs also provide valuable training to Air Wing 5’s landing signal officers (LSO). LSOs, or “paddles,” are naval aviators trained specifically to guide and ensure the safe recovery of aircraft aboard aircraft carriers.

“Today, specifically, the ‘paddles’ are training on the manually operated visual landing aid system (MOVLAS),” said Lt. Cmdr. Tory West, an LSO attached to CVW-5. “The pilots have to respond to the MOVLAS system differently, so if the ship is moving differently, the pilots can adjust and land safely.”

Although Iwo To offers an invaluable training opportunity for fixed-wing pilots and aircrew, it does come with its challenges. Iwo To is not suitable as a permanent FCLP site because of the difficulty in maintaining its remote facilities and its lack of optional airfields for use during inclement weather or other emergency situations. The U.S. government reserves the right to conduct FCLP at alternate mainland facilities when required.

“If there is an issue on the field, whereas if we had an area to conduct FCLPs much closer to land, it would provide much bigger safety margins for us to operate and train,” Fallon said.

Air Wing 5 includes the EA-18 Growlers of Electronic Attack Squadron (VAQ) 141, the E-2 Hawkeyes of Airborne Command and Control Squadron (VAW) 125, the MH-60S Seahawk helicopters of Helicopter Sea Combat Squadron (HSC) 12, the F-35 Lightning IIs of Strike Fighter Squadron (VFA) 147 and the F/A-18F and F/A-18E Super Hornets of VFA-102.

Air Wing 5 became America’s first permanently forward-deployed air wing in 1973, when it embarked with the first-in-class aircraft carrier, USS Midway (CV 41), in Japan.

Written by Petty Officer 1st Class Brian Reynolds with Commander, Naval Forces Japan.

PATUXENT RIVER, Md.—The Naval Aviation School for Additive Manufacturing (NASAM) is fostering collaboration across forces to ensure lethality and readiness wherever warfighters need it.

Recently, two U.S. Army soldiers used the skills they learned at NASAM to produce critical parts while deployed in support of Combined Joint Task Force–Operation Inherent Resolve.

Spc. James Martin and Spc. Harry Vo, soldiers from the U.S. Army 10th Mountain Division’s Allied Trades Team (Bravo Company, 10th Brigade Support Battalion, 1st Brigade Combat Team), recently applied their NASAM training to address critical equipment needs during deployment.

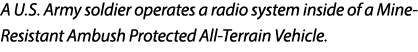

When Task Force Wolverine experienced limitations with their Starshield communications system because of a lack of an antenna mount for Mine-Resistant Ambush Protected vehicles, Martin and Vo designed and 3D-printed a mounting bracket that met all operational requirements. Their solution provided favorable antenna positioning, robust protection and reduced damage risk while maintaining full functionality of the vehicle’s emergency hatch and turret and maximizing connectivity.

Martin and Vo produced the prototype using acrylonitrile styrene acrylate, a highly durable polymer with robust UV and heat resistance. Though this specific material was not covered in their NASAM training, the foundational knowledge they learned at the school helped them adapt to using different systems and materials.

Their additive manufacturing (AM) solution also reduced manufacturing time and costs dramatically.

“This successful cross-service training demonstrates how AM capabilities can provide immediate solutions to operational challenges across the Department of Defense,” said Theodore Gronda, Naval Air Systems Command’s (NAVAIR) AM program manager. “When supply chains can’t deliver, AM delivers.”

While primarily established for Navy and Marine Corps personnel, NASAM accommodates students from other military branches occasionally. The six-week program, hosted by the Institute for Advanced Learning and Research in Danville, Virginia, provides foundational skills in AM that train maintenance personnel to produce supply-chain-gapped parts on site and on demand.

“AM’s mission is to improve operational readiness and lethality,” said Capt. Alexander Peabody, senior fleet liaison for NAVAIR AM. “The reality is that even during peacetime, supply chain disruptions necessitate the ability to reverse engineer or redesign components to maintain the operational capability of ships and aircraft.”

NASAM began with a pilot cohort of 12 students in February 2024 and continues to train military maintenance personnel in AM technologies.

For more information on NASAM, visit https://www.ialr.org/nasam/.

From the NAVAIR Additive Manufacturing Program

Office.

Carrier Air Wing 5 Operates at Iwo To

IWO TO, Japan—Aircrew from the Navy’s only forward-deployed air wing completed another qualification milestone with Field Carrier Landing Practices (FCLPs) at Iwo To, Japan, May 19 through 31.

FCLP is a required flight training for pilot qualification and proficiency that precedes aircraft carrier landing operations, ensuring warfighting readiness in support of regional security and stability in the U.S. Indo-Pacific region.

“[This is the training] that is required for Air Wing 5 air crews to get ready to go to sea,” said Capt. William Fallon, assistant chief of staff for Commander, U.S. Naval Forces Japan/Navy Region Japan. “[There is a great] amount of effort in the practice and the professionalism that goes into learning how to do this. [The] carrier environment is very challenging to work in—whether it’s daytime or nighttime. A large carrier suddenly feels very small when you do it, so it’s incumbent on us to practice realistically as we found right here, which is the benefit of Iwo To. It’s very dark at night, so it feels similar to our carrier environment.”

The routine training is required for all pilots of fixed-wing aircraft assigned to the Nimitz-class aircraft carrier USS George Washington (CVN 73). The types of aircraft that participate in FCLP are F-35C Lightning IIs, F/A-18E/F Super Hornets, EA-18G Growlers and E-2D Hawkeyes.

FCLPs also provide valuable training to Air Wing 5’s landing signal officers (LSO). LSOs, or “paddles,” are naval aviators trained specifically to guide and ensure the safe recovery of aircraft aboard aircraft carriers.

“Today, specifically, the ‘paddles’ are training on the manually operated visual landing aid system (MOVLAS),” said Lt. Cmdr. Tory West, an LSO attached to CVW-5. “The pilots have to respond to the MOVLAS system differently, so if the ship is moving differently, the pilots can adjust and land safely.”

Although Iwo To offers an invaluable training opportunity for fixed-wing pilots and aircrew, it does come with its challenges. Iwo To is not suitable as a permanent FCLP site because of the difficulty in maintaining its remote facilities and its lack of optional airfields for use during inclement weather or other emergency situations. The U.S. government reserves the right to conduct FCLP at alternate mainland facilities when required.

“If there is an issue on the field, whereas if we had an area to conduct FCLPs much closer to land, it would provide much bigger safety margins for us to operate and train,” Fallon said.

Air Wing 5 includes the EA-18 Growlers of Electronic Attack Squadron (VAQ) 141, the E-2 Hawkeyes of Airborne Command and Control Squadron (VAW) 125, the MH-60S Seahawk helicopters of Helicopter Sea Combat Squadron (HSC) 12, the F-35 Lightning IIs of Strike Fighter Squadron (VFA) 147 and the F/A-18F and F/A-18E Super Hornets of VFA-102.

Air Wing 5 became America’s first permanently forward-deployed air wing in 1973, when it embarked with the first-in-class aircraft carrier, USS Midway (CV 41), in Japan.

Written by Petty Officer 1st Class Brian Reynolds with Commander, Naval Forces Japan.

PATUXENT RIVER, Md.—The Naval Aviation School for Additive Manufacturing (NASAM) is fostering collaboration across forces to ensure lethality and readiness wherever warfighters need it.

Recently, two U.S. Army soldiers used the skills they learned at NASAM to produce critical parts while deployed in support of Combined Joint Task Force–Operation Inherent Resolve.

Spc. James Martin and Spc. Harry Vo, soldiers from the U.S. Army 10th Mountain Division’s Allied Trades Team (Bravo Company, 10th Brigade Support Battalion, 1st Brigade Combat Team), recently applied their NASAM training to address critical equipment needs during deployment.

When Task Force Wolverine experienced limitations with their Starshield communications system because of a lack of an antenna mount for Mine-Resistant Ambush Protected vehicles, Martin and Vo designed and 3D-printed a mounting bracket that met all operational requirements. Their solution provided favorable antenna positioning, robust protection and reduced damage risk while maintaining full functionality of the vehicle’s emergency hatch and turret and maximizing connectivity.

Martin and Vo produced the prototype using acrylonitrile styrene acrylate, a highly durable polymer with robust UV and heat resistance. Though this specific material was not covered in their NASAM training, the foundational knowledge they learned at the school helped them adapt to using different systems and materials.

Their additive manufacturing (AM) solution also reduced manufacturing time and costs dramatically.

“This successful cross-service training demonstrates how AM capabilities can provide immediate solutions to operational challenges across the Department of Defense,” said Theodore Gronda, Naval Air Systems Command’s (NAVAIR) AM program manager. “When supply chains can’t deliver, AM delivers.”

While primarily established for Navy and Marine Corps personnel, NASAM accommodates students from other military branches occasionally. The six-week program, hosted by the Institute for Advanced Learning and Research in Danville, Virginia, provides foundational skills in AM that train maintenance personnel to produce supply-chain-gapped parts on site and on demand.

“AM’s mission is to improve operational readiness and lethality,” said Capt. Alexander Peabody, senior fleet liaison for NAVAIR AM. “The reality is that even during peacetime, supply chain disruptions necessitate the ability to reverse engineer or redesign components to maintain the operational capability of ships and aircraft.”

NASAM began with a pilot cohort of 12 students in February 2024 and continues to train military maintenance personnel in AM technologies.

For more information on NASAM, visit https://www.ialr.org/nasam/.

From the NAVAIR Additive Manufacturing Program

Office.

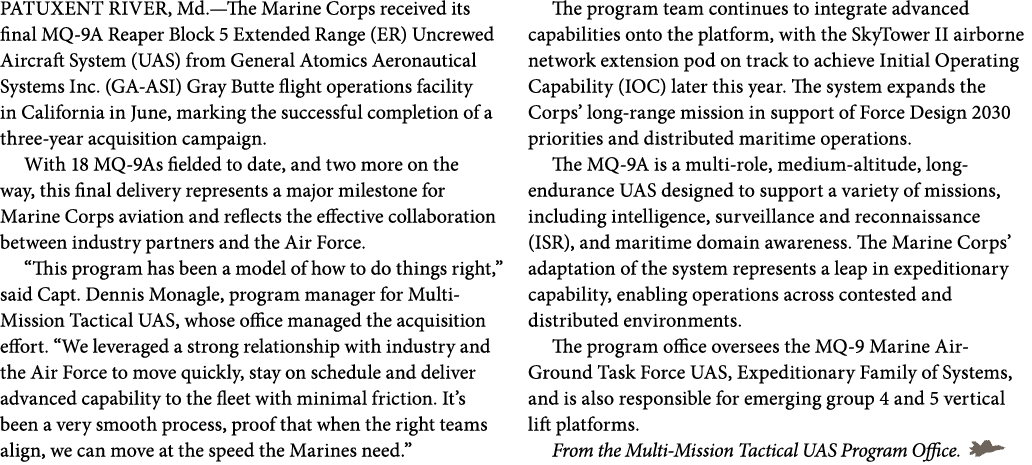

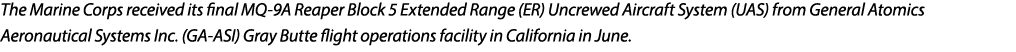

Marine Corps Receives Final MQ-9A Reaper, Concluding Rapid Delivery Effort

PATUXENT RIVER, Md.—The Marine Corps received its final MQ-9A Reaper Block 5 Extended Range (ER) Uncrewed Aircraft System (UAS) from General Atomics Aeronautical Systems Inc. (GA-ASI) Gray Butte flight operations facility in California in June, marking the successful completion of a three-year acquisition campaign.

With 18 MQ-9As fielded to date, and two more on the way, this final delivery represents a major milestone for Marine Corps aviation and reflects the effective collaboration between industry partners and the Air Force.

“This program has been a model of how to do things right,” said Capt. Dennis Monagle, program manager for Multi-Mission Tactical UAS, whose office managed the acquisition effort. “We leveraged a strong relationship with industry and the Air Force to move quickly, stay on schedule and deliver advanced capability to the fleet with minimal friction. It’s been a very smooth process, proof that when the right teams align, we can move at the speed the Marines need.”

The program team continues to integrate advanced capabilities onto the platform, with the SkyTower II airborne network extension pod on track to achieve Initial Operating Capability (IOC) later this year. The system expands the Corps’ long-range mission in support of Force Design 2030 priorities and distributed maritime operations.

The MQ-9A is a multi-role, medium-altitude, long-endurance UAS designed to support a variety of missions, including intelligence, surveillance and reconnaissance (ISR), and maritime domain awareness. The Marine Corps’ adaptation of the system represents a leap in expeditionary capability, enabling operations across contested and distributed environments.

The program office oversees the MQ-9 Marine Air-Ground Task Force UAS, Expeditionary Family of Systems, and is also responsible for emerging group 4 and 5 vertical lift platforms.

From the Multi-Mission Tactical UAS Program Office.

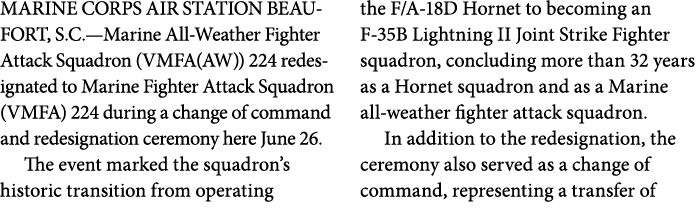

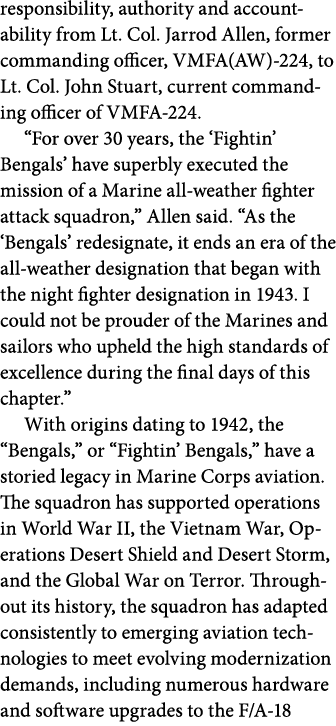

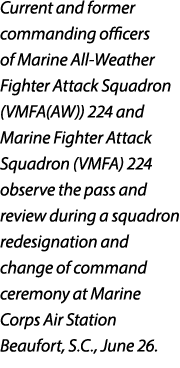

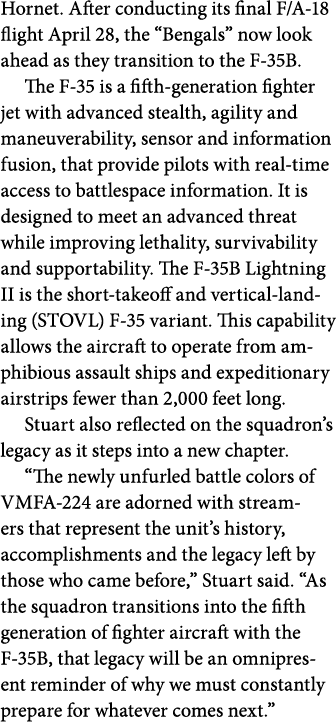

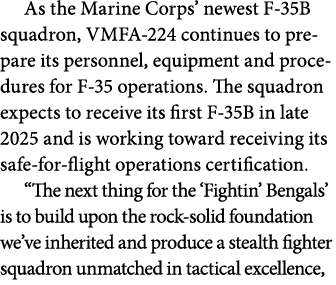

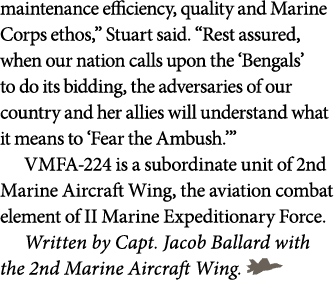

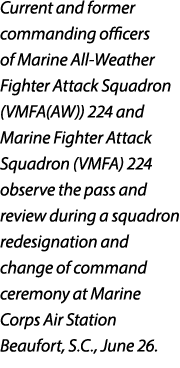

VMFA-224 Redesignated as Marine Corps’

Newest F-35B Squadron

MARINE CORPS AIR STATION BEAUFORT, S.C.—Marine All-Weather Fighter Attack Squadron (VMFA(AW)) 224 redesignated to Marine Fighter Attack Squadron (VMFA) 224 during a change of command and redesignation ceremony here June 26.

The event marked the squadron’s historic transition from operating the F/A-18D Hornet to becoming an F-35B Lightning II Joint Strike Fighter squadron, concluding more than 32 years as a Hornet squadron and as a Marine all-weather fighter attack squadron.

In addition to the redesignation, the ceremony also served as a change of command, representing a transfer of responsibility, authority and accountability from Lt. Col. Jarrod Allen, former commanding officer, VMFA(AW)-224, to Lt. Col. John Stuart, current commanding officer of VMFA-224.

“For over 30 years, the ‘Fightin’ Bengals’ have superbly executed the mission of a Marine all-weather fighter attack squadron,” Allen said. “As the ‘Bengals’ redesignate, it ends an era of the all-weather designation that began with the night fighter designation in 1943. I could not be prouder of the Marines and sailors who upheld the high standards of excellence during the final days of this chapter.”

With origins dating to 1942, the “Bengals,” or “Fightin’ Bengals,” have a storied legacy in Marine Corps aviation. The squadron has supported operations in World War II, the Vietnam War, Operations Desert Shield and Desert Storm, and the Global War on Terror. Throughout its history, the squadron has adapted consistently to emerging aviation technologies to meet evolving modernization demands, including numerous hardware and software upgrades to the F/A-18 Hornet. After conducting its final F/A-18 flight April 28, the “Bengals” now look ahead as they transition to the F-35B.

The F-35 is a fifth-generation fighter jet with advanced stealth, agility and maneuverability, sensor and information fusion, that provide pilots with real-time access to battlespace information. It is designed to meet an advanced threat while improving lethality, survivability and supportability. The F-35B Lightning II is the short-takeoff and vertical-landing (STOVL) F-35 variant. This capability allows the aircraft to operate from amphibious assault ships and expeditionary airstrips fewer than 2,000 feet long.

Stuart also reflected on the squadron’s legacy as it steps into a new chapter.

“The newly unfurled battle colors of VMFA-224 are adorned with streamers that represent the unit’s history, accomplishments and the legacy left by those who came before,” Stuart said. “As the squadron transitions into the fifth generation of fighter aircraft with the F-35B, that legacy will be an omnipresent reminder of why we must constantly prepare for whatever comes next.”

As the Marine Corps’ newest F-35B squadron, VMFA-224 continues to prepare its personnel, equipment and procedures for F-35 operations. The squadron expects to receive its first F-35B in late 2025 and is working toward receiving its safe-for-flight operations certification.

“The next thing for the ‘Fightin’ Bengals’ is to build upon the rock-solid foundation we’ve inherited and produce a stealth fighter squadron unmatched in tactical excellence, maintenance efficiency, quality and Marine Corps ethos,” Stuart said. “Rest assured, when our nation calls upon the ‘Bengals’ to do its bidding, the adversaries of our country and her allies will understand what it means to ‘Fear the Ambush.’”

VMFA-224 is a subordinate unit of 2nd Marine Aircraft Wing, the aviation combat element of II Marine Expeditionary Force.

Written by Capt. Jacob Ballard with the 2nd Marine Aircraft Wing.

Marine Corps Receives Final MQ-9A Reaper, Concluding Rapid Delivery Effort

PATUXENT RIVER, Md.—The Marine Corps received its final MQ-9A Reaper Block 5 Extended Range (ER) Uncrewed Aircraft System (UAS) from General Atomics Aeronautical Systems Inc. (GA-ASI) Gray Butte flight operations facility in California in June, marking the successful completion of a three-year acquisition campaign.

With 18 MQ-9As fielded to date, and two more on the way, this final delivery represents a major milestone for Marine Corps aviation and reflects the effective collaboration between industry partners and the Air Force.

“This program has been a model of how to do things right,” said Capt. Dennis Monagle, program manager for Multi-Mission Tactical UAS, whose office managed the acquisition effort. “We leveraged a strong relationship with industry and the Air Force to move quickly, stay on schedule and deliver advanced capability to the fleet with minimal friction. It’s been a very smooth process, proof that when the right teams align, we can move at the speed the Marines need.”

The program team continues to integrate advanced capabilities onto the platform, with the SkyTower II airborne network extension pod on track to achieve Initial Operating Capability (IOC) later this year. The system expands the Corps’ long-range mission in support of Force Design 2030 priorities and distributed maritime operations.

The MQ-9A is a multi-role, medium-altitude, long-endurance UAS designed to support a variety of missions, including intelligence, surveillance and reconnaissance (ISR), and maritime domain awareness. The Marine Corps’ adaptation of the system represents a leap in expeditionary capability, enabling operations across contested and distributed environments.

The program office oversees the MQ-9 Marine Air-Ground Task Force UAS, Expeditionary Family of Systems, and is also responsible for emerging group 4 and 5 vertical lift platforms.

From the Multi-Mission Tactical UAS Program Office.

VMFA-224 Redesignated as Marine Corps’

Newest F-35B Squadron

MARINE CORPS AIR STATION BEAUFORT, S.C.—Marine All-Weather Fighter Attack Squadron (VMFA(AW)) 224 redesignated to Marine Fighter Attack Squadron (VMFA) 224 during a change of command and redesignation ceremony here June 26.

The event marked the squadron’s historic transition from operating the F/A-18D Hornet to becoming an F-35B Lightning II Joint Strike Fighter squadron, concluding more than 32 years as a Hornet squadron and as a Marine all-weather fighter attack squadron.

In addition to the redesignation, the ceremony also served as a change of command, representing a transfer of responsibility, authority and accountability from Lt. Col. Jarrod Allen, former commanding officer, VMFA(AW)-224, to Lt. Col. John Stuart, current commanding officer of VMFA-224.

“For over 30 years, the ‘Fightin’ Bengals’ have superbly executed the mission of a Marine all-weather fighter attack squadron,” Allen said. “As the ‘Bengals’ redesignate, it ends an era of the all-weather designation that began with the night fighter designation in 1943. I could not be prouder of the Marines and sailors who upheld the high standards of excellence during the final days of this chapter.”

With origins dating to 1942, the “Bengals,” or “Fightin’ Bengals,” have a storied legacy in Marine Corps aviation. The squadron has supported operations in World War II, the Vietnam War, Operations Desert Shield and Desert Storm, and the Global War on Terror. Throughout its history, the squadron has adapted consistently to emerging aviation technologies to meet evolving modernization demands, including numerous hardware and software upgrades to the F/A-18 Hornet. After conducting its final F/A-18 flight April 28, the “Bengals” now look ahead as they transition to the F-35B.

The F-35 is a fifth-generation fighter jet with advanced stealth, agility and maneuverability, sensor and information fusion, that provide pilots with real-time access to battlespace information. It is designed to meet an advanced threat while improving lethality, survivability and supportability. The F-35B Lightning II is the short-takeoff and vertical-landing (STOVL) F-35 variant. This capability allows the aircraft to operate from amphibious assault ships and expeditionary airstrips fewer than 2,000 feet long.

Stuart also reflected on the squadron’s legacy as it steps into a new chapter.

“The newly unfurled battle colors of VMFA-224 are adorned with streamers that represent the unit’s history, accomplishments and the legacy left by those who came before,” Stuart said. “As the squadron transitions into the fifth generation of fighter aircraft with the F-35B, that legacy will be an omnipresent reminder of why we must constantly prepare for whatever comes next.”

As the Marine Corps’ newest F-35B squadron, VMFA-224 continues to prepare its personnel, equipment and procedures for F-35 operations. The squadron expects to receive its first F-35B in late 2025 and is working toward receiving its safe-for-flight operations certification.

“The next thing for the ‘Fightin’ Bengals’ is to build upon the rock-solid foundation we’ve inherited and produce a stealth fighter squadron unmatched in tactical excellence, maintenance efficiency, quality and Marine Corps ethos,” Stuart said. “Rest assured, when our nation calls upon the ‘Bengals’ to do its bidding, the adversaries of our country and her allies will understand what it means to ‘Fear the Ambush.’”

VMFA-224 is a subordinate unit of 2nd Marine Aircraft Wing, the aviation combat element of II Marine Expeditionary Force.

Written by Capt. Jacob Ballard with the 2nd Marine Aircraft Wing.

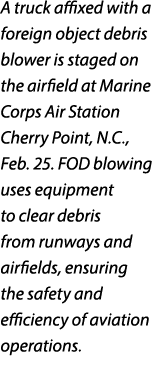

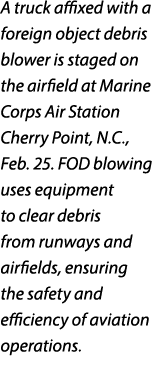

Blown Away: New FOD Removal Method Enhances Safety

MARINE CORPS AIR STATION CHERRY POINT, N.C.—Foreign object debris, or FOD, poses a hazard on flight lines and can threaten the safety of personnel, equipment and aircraft. To minimize these risks, Marine Corps Air Station (MCAS) Cherry Point, North Carolina, has shifted from physically picking up debris to the more efficient method of blowing the debris away. This change in protocol not only accelerates removing hazardous objects but also enhances safety because it reduces potential damage to aircraft and ensures a cleaner working environment for everyone on the flight line.

FOD blowing involves using air-powered equipment to clear objects, debris or material from runways, taxiways and airfields.

FOD can accumulate on the airfield when items fall off vehicles or aircraft passes through the area. Common debris includes rocks, screws and bolts. Organic materials can be blown off the flight line with a blower, whereas other foreign objects, such as screws and metal fasteners, must still be retrieved by hand and documented.

“We’re able to give pilots peace of mind, knowing that they can take off and land on a clean and clear runway,” said Sean Wales, an FOD attendant. “FOD blowing has made a huge impact for safety on the airfield.”

Wales said debris left on the airfield is hazardous to both aircraft and personnel. For example, if an aircraft were to encounter a sharp object, it could puncture a tire and deflate, or the engine could potentially ingest the debris, resulting in serious damage to equipment, costly repairs and significant injuries to passengers aboard aircraft.

While MCAS Cherry Point was the first Marine Corps air station to implement FOD blowers, Marine Corps air stations across the globe are adopting the new technology. Results have shown it maximizes the safety of aircraft and personnel and saves taxpayer dollars.

“Since being here, it has been night and day for FOD incidents on the runway,” said Scott Nickson, FOD supervisor. “Numbers have gone down significantly since we have been going out daily to remove FOD from the operating surfaces. It’s everyone doing their part to make the whole process safe.”

Written by Lance Cpl. Lauralle Gavilanes, Marine Corps Air Station Cherry Point, North Carolina.

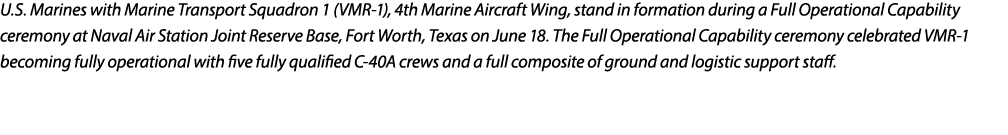

VMR-1 Celebrates Classification as Full Operational Capability Squadron

FORT WORTH, Texas—Marine Transport Squadron (VMR)-1 conducted a ceremony to celebrate achieving full operational capability with the C-40A aircraft at Naval Air Station Joint Reserve Base Fort Worth, Texas, June 18.

U.S. Rep. Marc Veasey (D-Texas, 33rd) and Texas Rep. Keresa Richardson (R-Collin County) joined Marines and their families to commemorate VMR-1’s readiness achievement. Their attendance showcased the strong community relations and local support that have helped strengthen the squadron’s mission and connection to North Texas.

Since receiving the C-40A aircraft in June 2023, VMR-1 has transported more than 11,000 passengers and 1.2 million pounds of cargo. Today, the squadron operates with five C-40A crews, supported by ground and logistics staff.

“We directly support numerous missions for the Marine Corps,” said Lt. Col. Hanson W. Pitchford, commanding officer, Marine Transport Squadron (VMR) 1, Marine Aircraft Group 41, 4th Marine Aircraft Wing, Marine Forces Reserve. “We’re tasked out with really once-in-a-lifetime missions, some of which were to Australia, New Caledonia, Papua New Guinea and the Philippines, as well as flying into Europe and the Middle East.”

VMR-1 has demonstrated its global reach by transporting the commandant of the Marine Corps to Iwo Jima for the 80th anniversary of the historic World War II battle, honoring the legacy of the Marines who fought and fell there.

Earlier this year, the squadron also transported the Marine Forces Reserve Band to Panama, where the band performed for local audiences and strengthened partnerships through cultural exchange.

“We like supporting Marines. It’s a lot more fun for us to have Marines in the back,” Pitchford said. “Marines are always really excited when they see these planes. So, they’re very happy to fly.”

With its full operational capability declared, VMR-1 stands ready to deliver agile, long-range airlift in support of Marines worldwide. VMR-1’s upcoming missions include exercise Arctic Edge 2025 in Alaska, further proving its place as a vital force multiplier for the Marine Corps.

“Flying in Arctic Edge 2025 … will be something that we probably look to continue into the future—flying these planes long distances in cold weather or austere environments. So that’s something we’re training towards,” Pitchford said. “It’s something we’re helping out with the larger Marine Corps. We’re also developing plans for next year, where we continue to push what can be done with the planes, establish the precedents of how we do direct support.”

Written by Cpl. Kanoa Thomas with the Marine Forces Reserve.

Blown Away: New FOD Removal Method Enhances Safety

MARINE CORPS AIR STATION CHERRY POINT, N.C.—Foreign object debris, or FOD, poses a hazard on flight lines and can threaten the safety of personnel, equipment and aircraft. To minimize these risks, Marine Corps Air Station (MCAS) Cherry Point, North Carolina, has shifted from physically picking up debris to the more efficient method of blowing the debris away. This change in protocol not only accelerates removing hazardous objects but also enhances safety because it reduces potential damage to aircraft and ensures a cleaner working environment for everyone on the flight line.

FOD blowing involves using air-powered equipment to clear objects, debris or material from runways, taxiways and airfields.

FOD can accumulate on the airfield when items fall off vehicles or aircraft passes through the area. Common debris includes rocks, screws and bolts. Organic materials can be blown off the flight line with a blower, whereas other foreign objects, such as screws and metal fasteners, must still be retrieved by hand and documented.

“We’re able to give pilots peace of mind, knowing that they can take off and land on a clean and clear runway,” said Sean Wales, an FOD attendant. “FOD blowing has made a huge impact for safety on the airfield.”

Wales said debris left on the airfield is hazardous to both aircraft and personnel. For example, if an aircraft were to encounter a sharp object, it could puncture a tire and deflate, or the engine could potentially ingest the debris, resulting in serious damage to equipment, costly repairs and significant injuries to passengers aboard aircraft.

While MCAS Cherry Point was the first Marine Corps air station to implement FOD blowers, Marine Corps air stations across the globe are adopting the new technology. Results have shown it maximizes the safety of aircraft and personnel and saves taxpayer dollars.

“Since being here, it has been night and day for FOD incidents on the runway,” said Scott Nickson, FOD supervisor. “Numbers have gone down significantly since we have been going out daily to remove FOD from the operating surfaces. It’s everyone doing their part to make the whole process safe.”

Written by Lance Cpl. Lauralle Gavilanes, Marine Corps Air Station Cherry Point, North Carolina.

VMR-1 Celebrates Classification as Full Operational Capability Squadron

FORT WORTH, Texas—Marine Transport Squadron (VMR)-1 conducted a ceremony to celebrate achieving full operational capability with the C-40A aircraft at Naval Air Station Joint Reserve Base Fort Worth, Texas, June 18.

U.S. Rep. Marc Veasey (D-Texas, 33rd) and Texas Rep. Keresa Richardson (R-Collin County) joined Marines and their families to commemorate VMR-1’s readiness achievement. Their attendance showcased the strong community relations and local support that have helped strengthen the squadron’s mission and connection to North Texas.

Since receiving the C-40A aircraft in June 2023, VMR-1 has transported more than 11,000 passengers and 1.2 million pounds of cargo. Today, the squadron operates with five C-40A crews, supported by ground and logistics staff.

“We directly support numerous missions for the Marine Corps,” said Lt. Col. Hanson W. Pitchford, commanding officer, Marine Transport Squadron (VMR) 1, Marine Aircraft Group 41, 4th Marine Aircraft Wing, Marine Forces Reserve. “We’re tasked out with really once-in-a-lifetime missions, some of which were to Australia, New Caledonia, Papua New Guinea and the Philippines, as well as flying into Europe and the Middle East.”

VMR-1 has demonstrated its global reach by transporting the commandant of the Marine Corps to Iwo Jima for the 80th anniversary of the historic World War II battle, honoring the legacy of the Marines who fought and fell there.

Earlier this year, the squadron also transported the Marine Forces Reserve Band to Panama, where the band performed for local audiences and strengthened partnerships through cultural exchange.

“We like supporting Marines. It’s a lot more fun for us to have Marines in the back,” Pitchford said. “Marines are always really excited when they see these planes. So, they’re very happy to fly.”

With its full operational capability declared, VMR-1 stands ready to deliver agile, long-range airlift in support of Marines worldwide. VMR-1’s upcoming missions include exercise Arctic Edge 2025 in Alaska, further proving its place as a vital force multiplier for the Marine Corps.

“Flying in Arctic Edge 2025 … will be something that we probably look to continue into the future—flying these planes long distances in cold weather or austere environments. So that’s something we’re training towards,” Pitchford said. “It’s something we’re helping out with the larger Marine Corps. We’re also developing plans for next year, where we continue to push what can be done with the planes, establish the precedents of how we do direct support.”

Written by Cpl. Kanoa Thomas with the Marine Forces Reserve.

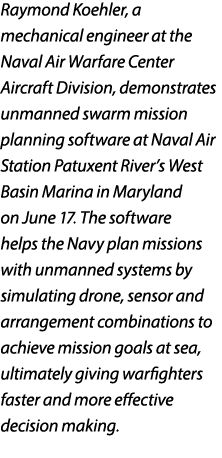

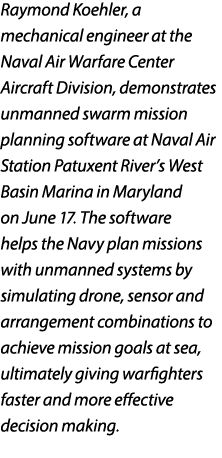

Navy Demonstrates Swarm Mission Planning Tech

PATUXENT RIVER, MD.—The Naval Air Warfare Center Aircraft Division (NAWCAD) demonstrated innovative mission planning software for swarms and other configurations of unmanned air, surface and underwater systems at its headquarters in June.

The new Optimized Cross-Domain Swarm Sensing (OCDSS) software program helps the Navy plan missions using groups of unmanned aircraft. By running thousands of computer simulations, the software determines the best combination and arrangement of drones and sensors to achieve mission goals at sea.

“Autonomy is the decisive edge for maritime dominance,” said NAWCAD Commander Rear Adm. Todd Evans. “This technology is critical to enhancing operations across domains and represents a significant step forward for manned-unmanned teaming.”

OCDSS helps the Navy and Marine Corps get the most out of their unmanned systems while saving time and money. Its computer simulations predict how different drones will perform together in various missions, enabling planners to choose the right number and type of vehicles for the job.

“OCDSS quickly runs thousands of simulations to predict how different unmanned systems might perform together,” said NAWCAD Mechanical Engineer Raymond Koehler, OCDSS’ lead software developer. “This software gives warfighters faster and more effective decision making—that’s competitive advantage.”

By providing a virtual testing environment, OCDSS also reduces the cost and time associated with real-world testing in defense acquisition programs, which aligns with industry practices where simulation drives up to 90 percent of the development process. The technology successfully operated at ANTX Coastal Trident in August 2024, focusing on port security and providing data for future development and deployment.

“OCDSS levels up how unmanned systems are used in a wide range of missions, and we’re ready to scale this autonomy to operational teams or test programs across the Navy and Marine Corps,” Koehler said.

Operational users and defense programs interested in learning more about OCDSS should contact NAWCAD tech team lead Derek Alley at derek.m.alley.civ@us.navy.mil for more information.

Koehler earned the Assistant Secretary of the Navy’s 2025 Dr. Delores M. Etter Top Scientists and Engineers of the Year Award in the Emergent Engineer category for his outstanding contributions to swarm autonomy. The team he supports also earned a NAWCAD award for its collaboration on the effort with the Naval Surface Warfare Center Carderock Division, Potomac, Maryland.

NAWCAD’s military, civilian and contract personnel operate test ranges, laboratories and aircraft in support of test, evaluation, research, development and sustainment for all Navy and Marine Corps aviation platforms. Based in Patuxent River, Maryland, NAWCAD also has major sites in St. Inigoes, Maryland; Lakehurst, New Jersey; and Orlando, Florida.

From the Naval Air Surface Warfare Aircraft Division.

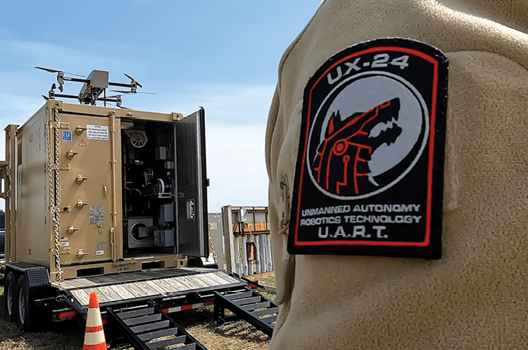

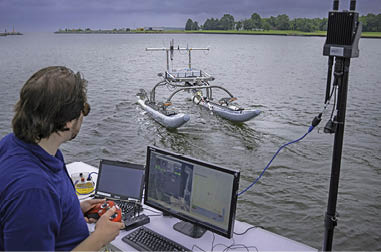

New Unmanned Test System Accelerates UAS Development at NAWCAD

PATUXENT RIVER, Md.—The Naval Air Warfare Center Aircraft Division (NAWCAD) is boosting its testing capabilities with a new UAS experimentation system showcased recently at a training event at Naval Air Station Patuxent River’s Webster Outlying Field.

Designed to accelerate unmanned aviation development, the Tethered Unmanned Aerial Vehicle Experimentation Payload System (TULEPS) allows developers to test software and mission equipment on a generic unmanned platform.

“When we test payloads on specific UAVs, it requires significant money, time and effort because of the limitations of the UAV; TULEPS is an innovative resource that allows us to focus first on the development of the actual payload technology,” said NAWCAD Lead Experimentation Engineer James Tomasic. “After we’ve worked through the technical issues and are comfortable with the payload, we can focus on implementing that technology on a specific UAV platform.”

TULEPS streamlines testing by allowing equipment to be loaded on its UAV without requiring flight clearances. Its tether enables systems to fly in most weather conditions, powers payloads for extended periods of time, transmits data securely and can be used on ships or trucks to give antennas and sensors a higher vantage point and longer reach.

“If we want to test an electronic warfare pod, a new communication antenna or an electro-optical surveillance sensor, we can put it on the TULEPS with very little paperwork,” said Chief Test Pilot Lt. Col. Jason Noll at NAWCAD’s unmanned Air Test and Evaluation Squadron (UX) 24. “The system is already approved, so we don’t have to obtain a new clearance—we can test on a shorter timeline with fewer man hours and save money as well.”

NAWCAD’s Experimentation Office (NEO) worked with industry partner DPI UAV Systems to stand up the new test capability quickly, which culminated in a two-day TULEPS event that featured classroom and hands-on training for more than 10 UX-24 air vehicle operators, the command’s first qualified TULEPS operators.

“NEO is here to help solve problems and support all of NAWCAD,” Tomasic said. “We are constantly looking at game-changing technologies like TULEPS that bring new capabilities to the warfare center.”

NAWCAD’s military, civilian and contract personnel operate test ranges, laboratories and aircraft in support of test, evaluation, research, development and sustainment for all Navy and Marine Corps aviation platforms. Based in Patuxent River, Maryland, NAWCAD also has major sites in St. Inigoes, Maryland; Lakehurst, New Jersey; and Orlando, Florida.

Written by Naval Air Warfare Center Aircraft Division Visual Information.

Navy Demonstrates Swarm Mission Planning Tech

PATUXENT RIVER, MD.—The Naval Air Warfare Center Aircraft Division (NAWCAD) demonstrated innovative mission planning software for swarms and other configurations of unmanned air, surface and underwater systems at its headquarters in June.

The new Optimized Cross-Domain Swarm Sensing (OCDSS) software program helps the Navy plan missions using groups of unmanned aircraft. By running thousands of computer simulations, the software determines the best combination and arrangement of drones and sensors to achieve mission goals at sea.

“Autonomy is the decisive edge for maritime dominance,” said NAWCAD Commander Rear Adm. Todd Evans. “This technology is critical to enhancing operations across domains and represents a significant step forward for manned-unmanned teaming.”

OCDSS helps the Navy and Marine Corps get the most out of their unmanned systems while saving time and money. Its computer simulations predict how different drones will perform together in various missions, enabling planners to choose the right number and type of vehicles for the job.

“OCDSS quickly runs thousands of simulations to predict how different unmanned systems might perform together,” said NAWCAD Mechanical Engineer Raymond Koehler, OCDSS’ lead software developer. “This software gives warfighters faster and more effective decision making—that’s competitive advantage.”

By providing a virtual testing environment, OCDSS also reduces the cost and time associated with real-world testing in defense acquisition programs, which aligns with industry practices where simulation drives up to 90 percent of the development process. The technology successfully operated at ANTX Coastal Trident in August 2024, focusing on port security and providing data for future development and deployment.

“OCDSS levels up how unmanned systems are used in a wide range of missions, and we’re ready to scale this autonomy to operational teams or test programs across the Navy and Marine Corps,” Koehler said.

Operational users and defense programs interested in learning more about OCDSS should contact NAWCAD tech team lead Derek Alley at derek.m.alley.civ@us.navy.mil for more information.

Koehler earned the Assistant Secretary of the Navy’s 2025 Dr. Delores M. Etter Top Scientists and Engineers of the Year Award in the Emergent Engineer category for his outstanding contributions to swarm autonomy. The team he supports also earned a NAWCAD award for its collaboration on the effort with the Naval Surface Warfare Center Carderock Division, Potomac, Maryland.

NAWCAD’s military, civilian and contract personnel operate test ranges, laboratories and aircraft in support of test, evaluation, research, development and sustainment for all Navy and Marine Corps aviation platforms. Based in Patuxent River, Maryland, NAWCAD also has major sites in St. Inigoes, Maryland; Lakehurst, New Jersey; and Orlando, Florida.

From the Naval Air Surface Warfare Aircraft Division.

New Unmanned Test System Accelerates UAS Development at NAWCAD

PATUXENT RIVER, Md.—The Naval Air Warfare Center Aircraft Division (NAWCAD) is boosting its testing capabilities with a new UAS experimentation system showcased recently at a training event at Naval Air Station Patuxent River’s Webster Outlying Field.

Designed to accelerate unmanned aviation development, the Tethered Unmanned Aerial Vehicle Experimentation Payload System (TULEPS) allows developers to test software and mission equipment on a generic unmanned platform.

“When we test payloads on specific UAVs, it requires significant money, time and effort because of the limitations of the UAV; TULEPS is an innovative resource that allows us to focus first on the development of the actual payload technology,” said NAWCAD Lead Experimentation Engineer James Tomasic. “After we’ve worked through the technical issues and are comfortable with the payload, we can focus on implementing that technology on a specific UAV platform.”

TULEPS streamlines testing by allowing equipment to be loaded on its UAV without requiring flight clearances. Its tether enables systems to fly in most weather conditions, powers payloads for extended periods of time, transmits data securely and can be used on ships or trucks to give antennas and sensors a higher vantage point and longer reach.

“If we want to test an electronic warfare pod, a new communication antenna or an electro-optical surveillance sensor, we can put it on the TULEPS with very little paperwork,” said Chief Test Pilot Lt. Col. Jason Noll at NAWCAD’s unmanned Air Test and Evaluation Squadron (UX) 24. “The system is already approved, so we don’t have to obtain a new clearance—we can test on a shorter timeline with fewer man hours and save money as well.”

NAWCAD’s Experimentation Office (NEO) worked with industry partner DPI UAV Systems to stand up the new test capability quickly, which culminated in a two-day TULEPS event that featured classroom and hands-on training for more than 10 UX-24 air vehicle operators, the command’s first qualified TULEPS operators.

“NEO is here to help solve problems and support all of NAWCAD,” Tomasic said. “We are constantly looking at game-changing technologies like TULEPS that bring new capabilities to the warfare center.”

NAWCAD’s military, civilian and contract personnel operate test ranges, laboratories and aircraft in support of test, evaluation, research, development and sustainment for all Navy and Marine Corps aviation platforms. Based in Patuxent River, Maryland, NAWCAD also has major sites in St. Inigoes, Maryland; Lakehurst, New Jersey; and Orlando, Florida.

Written by Naval Air Warfare Center Aircraft Division Visual Information.

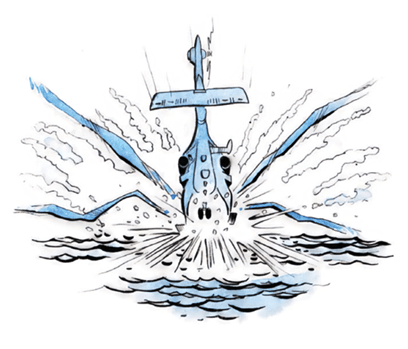

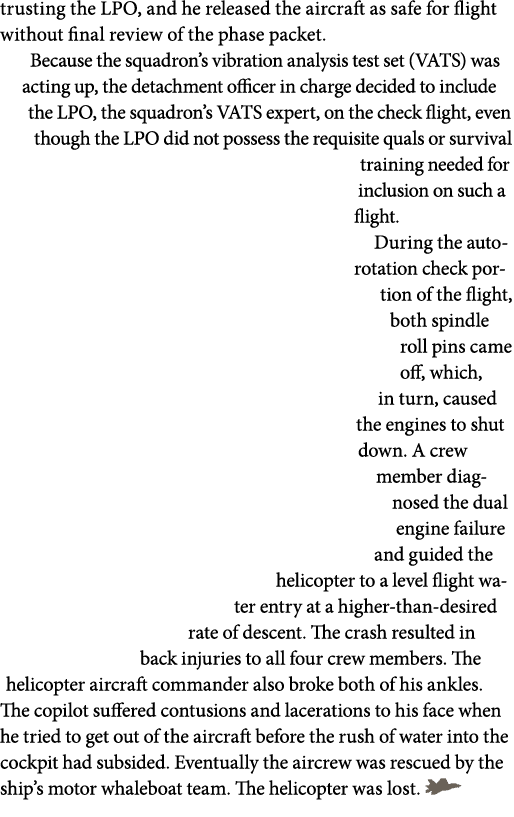

Post-Maintenance Check Flub

An H-60 was inducted into B-phase maintenance the evening prior to a four-day port visit. Early the next morning, the detatchment’s lead petty officer (LPO) started the day’s planned work on the aircraft, eager to finish to secure folks for liberty.

Since the LPO was the detatchment’s lead aviation machinist mate, he elected to remove and replace the engine load demand spindle roll pins. He’d done the procedure many times, so he elected not to use the technical manual.

After conducting the maintenance, the LPO also acted as the phase quality assurance representative (QAR), which is a direct violation of OPNAVINST 4790.2 (Naval Aviation Maintenance Program). The LPO knew this and went a step further but had another maintainer sign the paperwork as “worker” while he signed it as “QAR.” For his part, the other maintainer assumed he was signing the form for corrosion work he’d actually performed.

The detachment chief petty officer made the mistake of trusting the LPO, and he released the aircraft as safe for flight without final review of the phase packet.

Because the squadron’s vibration analysis test set (VATS) was acting up, the detachment officer in charge decided to include the LPO, the squadron’s VATS expert, on the check flight, even though the LPO did not possess the requisite quals or survival training needed for inclusion on such a flight.

During the autorotation check portion of the flight, both spindle roll pins came off, which, in turn, caused the engines to shut down. A crew member diagnosed the dual engine failure and guided the helicopter to a level flight water entry at a higher-than-desired rate of descent. The crash resulted in back injuries to all four crew members. The helicopter aircraft commander also broke both of his ankles. The copilot suffered contusions and lacerations to his face when he tried to get out of the aircraft before the rush of water into the cockpit had subsided. Eventually the aircrew was rescued by the ship’s motor whaleboat team. The helicopter was lost.

Grampaw Pettibone says…

These boys used every cliché in the book, didn’t they? From maintainers with liberty-itis skipping checklists and QA-ing their own work to faulty gear leading to bad supervisory calls up the chain of command, this mishap is chock full o‘ the lessons we done learned too many times. This squadron was lucky to get outta this pickle with some bad backs, a few broken bones and a lost helo.

Gramps has said these things near-on a million times, but obviously they needs to be said again: Use checklists. Follow OPNAV instructions to the letter.

’Nuff said? (Then why do I have the feeling I’ll be saying them again?)

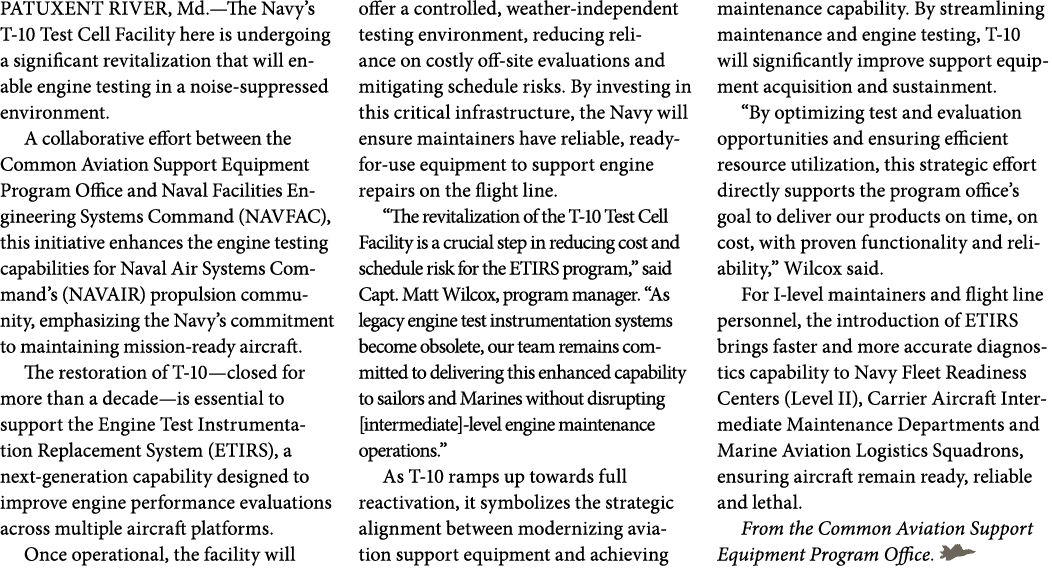

Navy Restores T-10 Test Cell Facility, Enhancing Fleet Readiness

PATUXENT RIVER, Md.—The Navy’s T-10 Test Cell Facility here is undergoing a significant revitalization that will enable engine testing in a noise-suppressed environment.

A collaborative effort between the Common Aviation Support Equipment Program Office and Naval Facilities Engineering Systems Command (NAVFAC), this initiative enhances the engine testing capabilities for Naval Air Systems Command’s (NAVAIR) propulsion community, emphasizing the Navy’s commitment to maintaining mission-ready aircraft.

The restoration of T-10—closed for more than a decade—is essential to support the Engine Test Instrumentation Replacement System (ETIRS), a next-generation capability designed to improve engine performance evaluations across multiple aircraft platforms.

Once operational, the facility will offer a controlled, weather-independent testing environment, reducing reliance on costly off-site evaluations and mitigating schedule risks. By investing in this critical infrastructure, the Navy will ensure maintainers have reliable, ready-for-use equipment to support engine repairs on the flight line.

“The revitalization of the T-10 Test Cell Facility is a crucial step in reducing cost and schedule risk for the ETIRS program,” said Capt. Matt Wilcox, program manager. “As legacy engine test instrumentation systems become obsolete, our team remains committed to delivering this enhanced capability to sailors and Marines without disrupting [intermediate]-level engine maintenance operations.”

As T-10 ramps up towards full reactivation, it symbolizes the strategic alignment between modernizing aviation support equipment and achieving maintenance capability. By streamlining maintenance and engine testing, T-10 will significantly improve support equipment acquisition and sustainment.

“By optimizing test and evaluation opportunities and ensuring efficient resource utilization, this strategic effort directly supports the program office’s goal to deliver our products on time, on cost, with proven functionality and reliability,” Wilcox said.